Chemical Manufacturers: Trends, Challenges, and Opportunities

When you hear chemical manufacturers, companies that make industrial chemicals, polymers, and specialty compounds for sectors ranging from agriculture to electronics. Also known as chemical producers, they keep supply chains moving and shape product costs worldwide.

One major relationship you’ll notice is that chemical manufacturers often supply raw materials to pharmaceutical manufacturers, firms that develop and produce medicines using bulk chemicals as active ingredients. The demand for new drugs pushes the chemical sector to innovate faster, especially in API (active pharmaceutical ingredient) synthesis. This link creates a feedback loop: as pharma chases cheaper, cleaner APIs, chemical producers adopt greener processes, which in turn lowers drug costs.

Another key player is the textile manufacturers, companies that turn fibers and yarns into fabrics, often needing dyes, finishes, and synthetic fibers produced by the chemical industry. When a textile mill needs a new water‑repellent coating, it turns to chemical firms for specialized polymers. Hence, innovations in polymer chemistry directly affect fabric performance, sustainability, and price points.

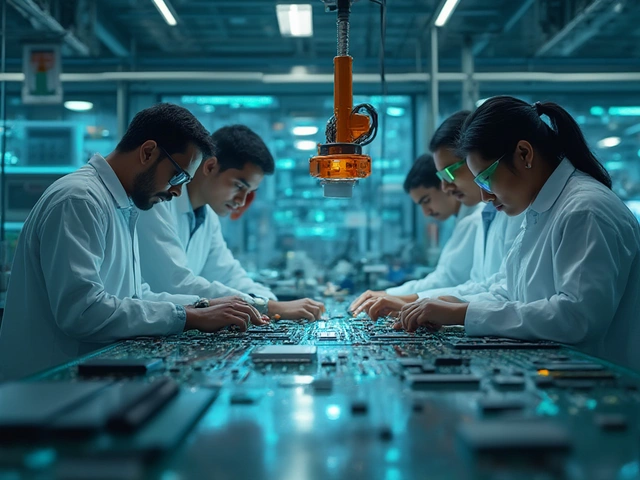

The electronics arena also leans heavily on chemicals. electronics manufacturers, businesses that assemble smartphones, chips, and other devices, relying on high‑purity solvents, photoresists, and specialty gases from chemical producers drive a constant need for ultra‑clean chemicals. As chip features shrink, the chemical side must meet tighter tolerances, prompting tighter quality control and investment in advanced processing equipment.

Why These Connections Matter for You

Understanding the web of relationships helps you spot where market shifts will hit next. If a new environmental regulation limits a certain solvent, both electronics and textile firms feel the pinch, and chemical manufacturers scramble to offer alternatives. Likewise, a breakthrough in biodegradable polymers can open a fast‑growing niche for sustainable textiles while giving pharma greener excipients.

Safety and compliance are another shared challenge. All three sectors—pharma, textiles, and electronics—must meet strict standards, so chemical manufacturers invest heavily in safety protocols, waste‑treatment tech, and certifications like ISO 9001. This investment raises overall industry reliability, but also adds cost pressure that trickles down the supply chain.

Looking ahead, the push for circular economy models is reshaping the chemical landscape. Companies are now designing chemicals that can be recycled back into the manufacturing loop, reducing raw‑material extraction. For pharma, this could mean reusable solvents; for textiles, recyclable dyes; for electronics, reclaimable etchants. The trend signals a future where chemical manufacturers are not just suppliers but partners in sustainability.

Below you’ll find a hand‑picked collection of articles that dive deeper into each of these themes—how global supply networks work, where the biggest growth opportunities lie, and what policies are reshaping the market. Use them to get practical insights, benchmark your own operations, or simply satisfy your curiosity about the fascinating world of chemical manufacturing.

Indian manufacturing, especially in the chemical sector, keeps hitting roadblocks despite big promises. Simple problems—like tricky regulations, high costs, and shaky infrastructure—hold businesses back. Chemical manufacturers face extra headaches with raw material imports and unpredictable policies. This article breaks down what’s really stopping growth, and shares tips for companies to survive in this tough scene. No jargon, just practical facts and advice. (Read More)

India's chemical industry is on the brink of significant change, driven by innovation, sustainability, and economic growth. This article explores the factors shaping the future of chemical manufacturing in India, including technological advancements, environmental challenges, and new market opportunities. Discover how policy changes and global demand are influencing manufacturers, and what strategic steps they can take. By understanding these dynamics, businesses can capitalize on emerging trends and contribute to India's economic progress. (Read More)

India's chemical industry plays a significant role on a global scale, with rapid growth in recent decades. The world's largest chemical manufacturer is a central topic for those interested in this field. This article explores who holds that title, highlighting the key industry's influencers and examining how India's chemical giants compare. It sheds light on the market dynamics and provides valuable insights into what makes a company rise to the top in this competitive landscape. (Read More)