Made-in-Nigeria Cars: What’s Happening and Why It Matters

When talking about Made-in-Nigeria cars, vehicles that are designed, assembled, or fully manufactured within Nigeria’s borders. Also known as Nigerian‑made vehicles, they reflect a growing push for domestic auto production, reduced imports, and new job opportunities.

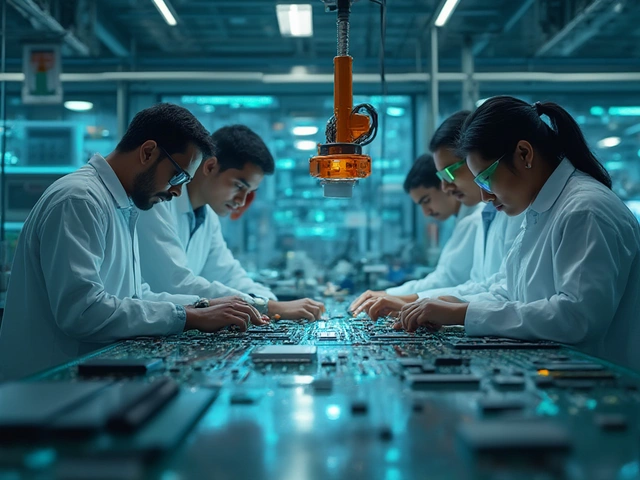

The Nigerian automotive industry, the network of manufacturers, suppliers, and service providers that builds cars and parts in Nigeria is still nascent but gaining momentum. Local manufacturing brings several benefits: it cuts shipping costs, builds a skilled workforce, and creates a supply chain that can support other sectors like steel and plastics. However, setting up a vehicle assembly plant, a facility where imported kits are put together into finished cars is not cheap. Companies need reliable power, trained technicians, and access to components that meet quality standards. When those pieces fall into place, the result is a car that can compete on price and relevance for Nigerian drivers.

Why Local Production is a Game‑Changer

One of the biggest drivers behind made-in-Nigeria cars is the idea of import substitution. This policy approach encourages manufacturers to replace foreign‑made parts with locally sourced ones, which in turn stimulates growth in related industries. For example, a local plant that needs steel frames creates demand for Nigerian steel mills, while a need for plastic dashboards supports local polymer producers. The government often backs this strategy with tax breaks, reduced tariffs, and financing schemes, making the business case more attractive.

But policies alone don’t guarantee success. The industry also faces real challenges: inconsistent electricity supply, limited access to high‑precision tooling, and a relatively small domestic market compared with imported models. Companies that manage to overcome these hurdles tend to focus on niche segments—like affordable compact cars, utility vehicles for rural use, or electric models suited to urban traffic. By tailoring products to local conditions, they can achieve better fuel efficiency, lower maintenance costs, and parts that are easier to find.

Another piece of the puzzle is skill development. When a plant hires engineers, line workers, and quality inspectors, it creates a talent pool that can spill over into other manufacturing areas. Training programs, often run in partnership with technical schools, help raise the overall competency of the workforce. This “human capital” effect means that even if a single car maker folds, the skills stay in the economy and can be redeployed.

Looking at neighboring markets gives perspective. Pakistan’s budding auto sector, for instance, relies heavily on joint ventures with foreign brands, while the United States still imports many components despite a strong domestic base. Nigeria can learn from both: adopt joint‑venture models to gain technology, but also protect and nurture home‑grown suppliers to avoid over‑dependence.

In practice, the growth of made‑in‑Nigeria cars shows up in three measurable ways. First, the share of locally assembled vehicles in total car sales has risen from under 5% a decade ago to close to 12% today. Second, the number of suppliers providing parts such as batteries, seat frames, and wiring harnesses has doubled, indicating a deepening ecosystem. Third, the average price gap between a fully imported car and a locally assembled equivalent has narrowed, making domestic options more attractive to buyers.

All these factors—policy support, skill development, supply chain expansion, and market adaptation—form a web of relationships that drive the sector forward. As the ecosystem matures, you’ll see more fully built‑in‑Nigeria models, not just assembled knock‑downs.

Below you’ll find a curated collection of articles that dig deeper into these topics, from the nitty‑gritty of setting up a factory to the broader impact on Nigeria’s economy. Each piece adds a layer to the picture, helping you understand where made‑in‑Nigeria cars are headed and what you can do to stay ahead of the curve.

Nigeria's automotive industry might surprise many, boasting local manufacturing initiatives. This article delves into which car brands are assembled in Nigeria, unveiling some unexpected partnerships and regional factories. It explores how the government's policies encourage local automotive production and the implications for the economy. Furthermore, it discusses the challenges these manufacturers face in Nigeria's unique market. (Read More)