Economic Downturn Opportunities

When looking at Economic Downturn Opportunities, the chances that firms can grow, innovate or cut costs during a recession. Also known as crisis‑driven growth, it encourages companies to rethink operations, tap new markets and sharpen efficiencies. A key way to capture these chances is through Local Manufacturing, producing goods closer to end‑users to lower logistics costs and boost regional jobs. During a slowdown, local factories often gain government incentives, and they can respond faster to shifting demand.

Why Crises Spark Innovation

Another powerful lever is Reshoring, the practice of bringing production back from overseas. Economic downturn opportunities push firms to evaluate offshore spending, especially when currency swings and trade barriers tighten. This reshoring wave fuels Supply Chain Diversification, spreading procurement across multiple sources to reduce risk. When a market contracts, diversified supply chains keep inventories balanced and prevent single‑point failures. Together these moves create a feedback loop: a downturn encourages reshoring, reshoring expands local manufacturing, and diversified supply chains make the whole system more resilient.

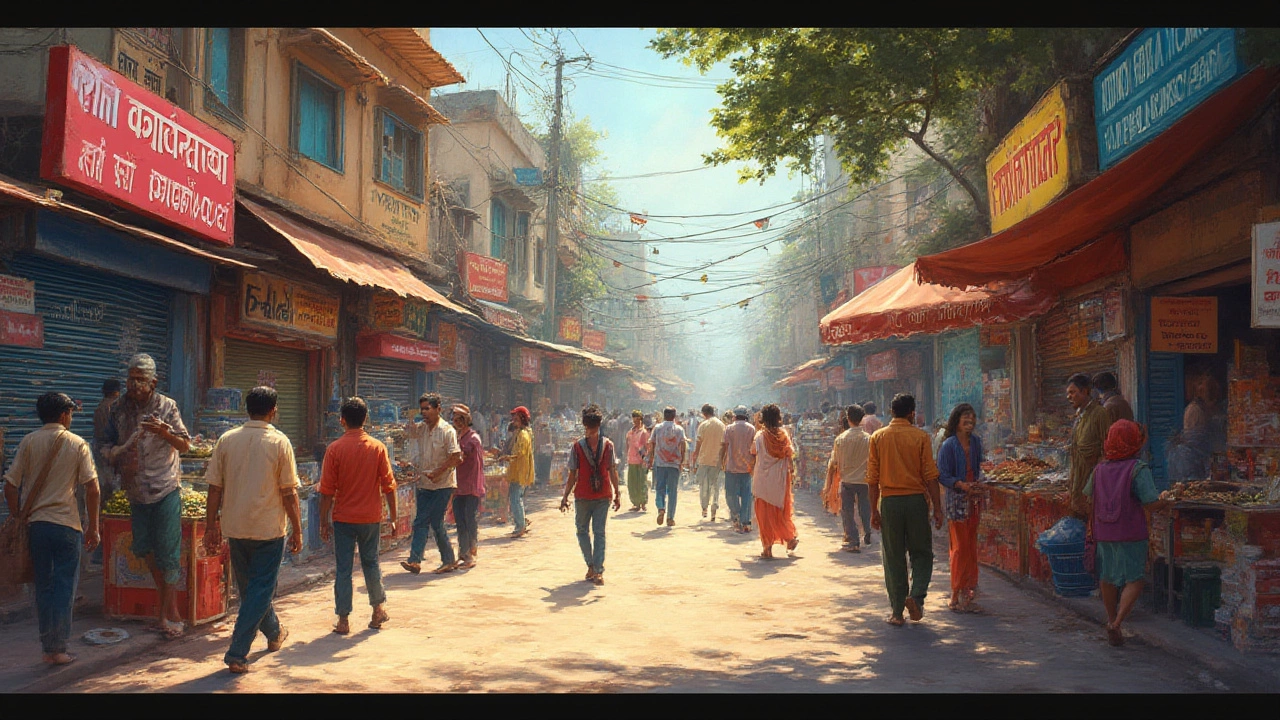

The collection below shows how Indian manufacturers, pharma giants, textile hubs and tech exporters are leveraging these tactics. You’ll see real‑world examples of how companies spot genuine opportunities, cut costs, and even launch new small‑business ideas during lean periods. Dive in to discover practical steps you can apply right now, whether you run a factory, a startup, or a supply‑chain team looking to turn a slowdown into a growth story.

Discover which businesses not only survive but boom during a recession. Get real examples, stats, and tips to spot the most resilient industries in tough times. (Read More)