Primary Processing: The Backbone of Modern Manufacturing

When working with Primary Processing, the first step that turns raw inputs into components ready for assembly. Also known as initial processing, it determines the quality, speed and cost of everything that follows.

Primary processing isn’t a stand‑alone activity; it lives inside a larger Manufacturing, the end‑to‑end creation of finished goods from raw material ecosystem. The better the initial shaping, cutting, or refining, the smoother the downstream steps become. In fact, primary processing encompasses material preparation, cleaning, size reduction, and basic forming – all of which feed directly into the assembly line.

One of the biggest drivers of success in primary processing is a well‑coordinated Supply Chain, the network that moves raw materials, components and finished products between suppliers, factories and markets. An efficient supply chain reduces lead times, cuts inventory costs and ensures the right grade of material arrives at the right time. When the supply chain falters, bottlenecks appear in primary processing, causing delays downstream and higher scrap rates.

Why Primary Processing Matters Across Industries

From textiles in Surat to pharma giants like Cipla, every sector relies on solid primary processing. In textiles, raw cotton or synthetic fibers must be cleaned, carded and spun before weaving. In pharmaceuticals, active ingredients undergo purification and granulation before tableting. The core idea stays the same: raw input → basic transformation → ready‑for‑assembly. That pattern explains why the tag collection includes articles on furniture materials, electronics exports and even steel production.

Local manufacturing brings another layer of relevance. When factories stay close to raw‑material sources, transportation costs drop and carbon footprints shrink. This Local Manufacturing, the practice of producing goods near the point of consumption or raw‑material extraction model often boosts primary processing efficiency because material handling becomes simpler and turnover faster. The posts on reshoring, domestic supply chains, and regional textile hubs all illustrate how location impacts the first processing steps.

Value addition is the hidden payoff of great primary processing. By turning a low‑grade raw input into a higher‑grade component, companies capture more margin early. For example, converting raw steel billets into rolled sheets adds significant value before the sheet is cut into automotive parts. The same principle applies to electronics, where raw silicon wafers become semi‑finished chips ready for assembly. Articles on semiconductor imports, electronics export leaders and difficult manufacturing processes all circle back to this value‑creation concept.

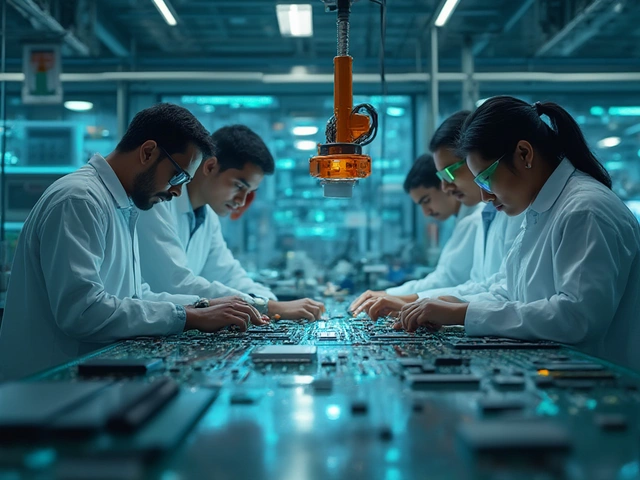

Technology is another catalyst. Modern CNC machines, laser cutters and robotic material handlers raise the precision of primary processing while slashing waste. Automation reduces the reliance on manual labor and lets factories switch between product lines faster. The post about “Most Difficult Manufacturing Process” highlights how advanced tools make once‑impossible steps routine, reinforcing the idea that primary processing requires the right equipment.

Skill development underpins all these advances. Workers who understand material behavior, machine settings and quality inspection can fine‑tune the primary processing stage to hit tighter tolerances. Training programs, vocational education and on‑the‑job apprenticeships therefore become strategic investments. The article on manufacturing benefits to local communities touches on this by showing how factories create skilled jobs that lift regional economies.

Regulation also plays a role. Standards for food‑grade plastics, pharmaceutical purity or steel composition dictate what primary processing methods are acceptable. Compliance adds a layer of complexity but also ensures market access. Posts about single‑use plastic bans and pharma industry rankings illustrate how policy shapes the early processing rules.

Finally, sustainability is now a core metric. Companies measure energy use, water consumption and waste generation during primary processing to meet ESG goals. Cleaner processes not only reduce environmental impact but also lower operating costs. The discussion on eco‑friendly manufacturing in India’s plastic ban article ties right back to how the first transformation step can set the tone for an entire product’s sustainability profile.

All these threads – technology, skills, regulation, location and value addition – intersect in the primary processing stage. Below you’ll find a curated set of articles that dive deeper into each angle, from raw material handling in the textile hub of Surat to the intricate supply chains that bring IKEA furniture to Indian homes. Explore the collection to see how the fundamentals of primary processing shape today’s manufacturing landscape.

This article breaks down the 3 levels of processing in food units, explaining what happens at each stage and why it matters. You'll find real-world examples, practical tips, and insights that make sense even if you're not an industry pro. From raw produce to ready-to-eat snacks, get the facts you need to understand how your food gets from the field to your plate. Perfect for anyone who wants a straightforward explanation or is looking to improve their own processing setup. No confusing jargon—just clear, helpful info. (Read More)